I am Silvio Bessone and I don’t tell lies!

I read in a post written by a world-renowned Master Pastry Chef, that Chocolate produced by an Artisan would not be safe, as it would not be able to guarantee bacteriological purity and food safety! Perhaps this is an attempt to shift the smear for the historical fakes of his friends?

So: let’s have some order! I am an artisan CHOCOLATE MAKER! I’ve been making my own chocolate for almost 20 years, and I don’t just roast cocoa. I traveled the world to understand! The where the information from the industries seemed biased and flawed, I began to research where cocoa came from and to be able to learn more about it I graduated with 110/110 with felicitations du Jury! Discussing back in December 5, 2006 the thesis on the correlation between industrial and Artisan productions! ” Biography of Artisan Chocolate”

In the meantime I began to travel the world in search of the best cocoa, or at least in search of understanding what generated the Biodiversity of the magical food of the Gods, once I understood how it worked I looked for those who sold cocoa in Europe, I found several but when I checked what they sold I often came across non-existent companies! So I started buying direct!!! The choice of small producers also came through training, financial support, sometimes even technical support, I hosted farmers in my home to teach them what and how it was to be done, I designed, pre-financed and then built a Center in SRI LANKA and we inaugurated it in November 2007 the Social center made for the post Tsunami, Now it is applied in 4 countries of the World My personal Method that is based on principles of Biodynamics and Ayurvedic Bessone Method Patent.

Image of Silvio Bessone at the entrance to the cocoa processing center in Matale, Sri Lanka

Cacao purchased from around the world is analyzed before importation certain values are measured: Mycotoxins, bacterial counts Bacterial counts and colony checks, as well as looking for possible contamination by Salmonella Listeria and fecal Staphylococci! when the analyses assure us of the integrity of the raw material it is imported and arrives at the company through Qualified Importers who pick up the cocoa at the port of embarkation and deliver it to Vicoforte through three ports mainly: Genoa Amsterdam and Hamburg. The cocoa is then stored in a cold room and kept at 14 degrees with a -20 temperature change once a month for 12 hours in order to degerminate any insects or larvae.

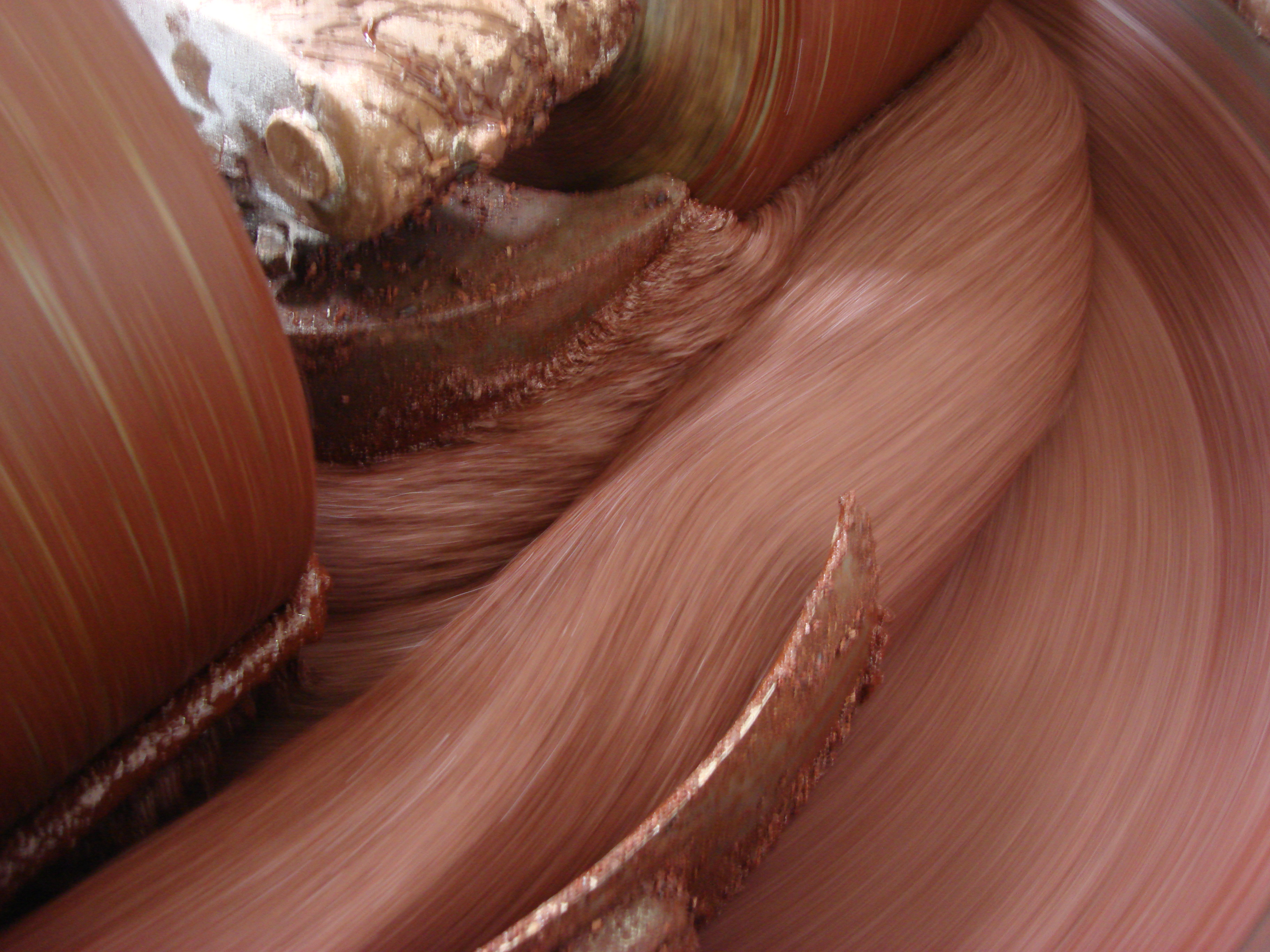

On the farm in Vicoforte it is stripped, dusted and if necessary Calibrated. The whole bean roasting process ensures that the cocoa is perfectly roasted and is later processed with PROFESSIONAL machinery ( no marbles blenders are used to produce chocolate!) such as to ensure that it is not a child’s play, The breaking of the beans with the related selection of the husks, removal of the germ, and the minudrino which are later used in other processing such as cosmetics, the production of Beers, and the production of Herbal Teas or Chocolate Bath. the rest of the pulp is processed into chocolate. Each Batch is 200-400-800 kg ( we will talk about this step in detail soon) and then is stored in tanks or blocks of 10 kg placed under vacuum and stored in a dehumidified cell at 14 degrees centigrade at least 40 days before use. I attach files of the analysis of the cocoa used

Analysis by Silvio Bessone regarding the batch of cocoa used to produce chocolate of origin

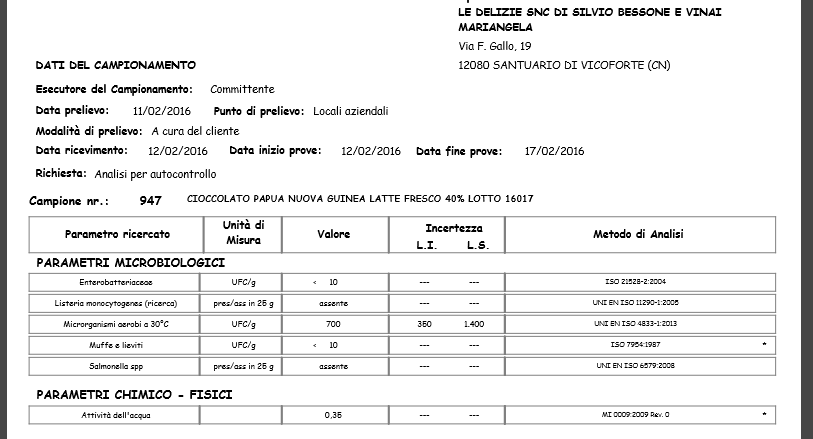

Chocolate is controlled and analyzed as much if not more than industries! The Bessone method guarantees TOTAL CONTROL ON PRODUCTION PROCESSES, I enclose the analysis of Milk Chocolate produced with the milk of my Cows raised by Farmer Rulfo 6 km from my farm and that with the EC Certificate S3C57 Ministerial recognition for the transformation of fresh milk from the Stable into Milk in Concentrate (powder) for the production of our Cow to Bar!!! ( if you’ve never heard of it write it down before I copy this too) I specify that the milk we use reports to the analysis Average bacterial loads 18/1000 and somatic loads of 4 months average 27/1000 the safety limits are 100/1000 and 400/1000. Under 100,000 you can process raw milk by law as it is defined as PERFECT, we are at 18,000 average!!! On the July batch we processed milk from two-year-old Mora Vacca mother of Stellina and daughter of Pavone, which has been in production again since September.

.Calling Artisan chocolate unsafe is a Cultural Crime, I feel compassion for those people who, not knowing how to raise their technical cultural level, denigrate those like me! Without bowing to any Mammasantissima chose BEFORE almost anyone else to walk a road that is fraught with pitfalls and yet today makes me at peace with the world and allows me to look at EVERYONE with my head held high and wait sitting on the riverbank for the next cultural tourist to pass by.

Cocoa cocoa pods are selected to improve cocoa uniformity

Ultimi commenti